Introduction

Vehicle-borne threats remain among the hardest to screen at scale. Checkpoints must process thousands of entries without creating bottlenecks, yet a single missed anomaly beneath a chassis can have outsized consequences. Under Vehicle Inspection Systems (UVIS) and Under Vehicle Surveillance Systems (UVSS) solve this dilemma by capturing high-resolution images of the undercarriage and using analytics to flag tampering, contraband, or improvised devices. Spectron Group, a seasoned UVIS/UVSS System Supplier, delivers end-to-end solutions hardware, analytics, integration, and training that make checkpoints faster and safer.

What UVIS and UVSS actually do

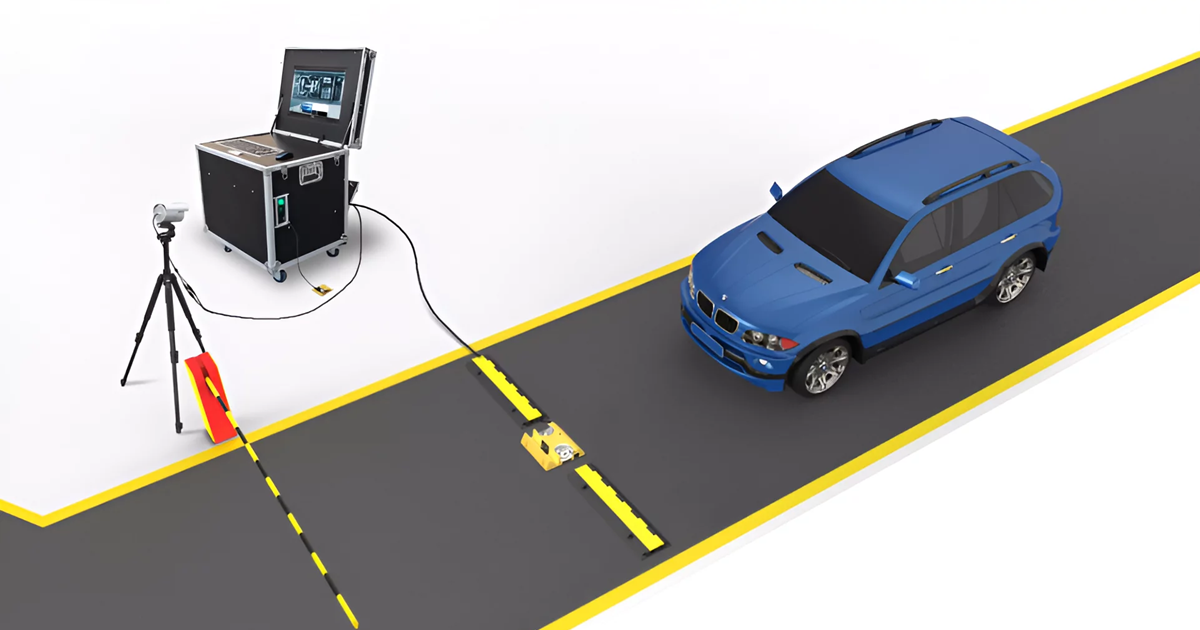

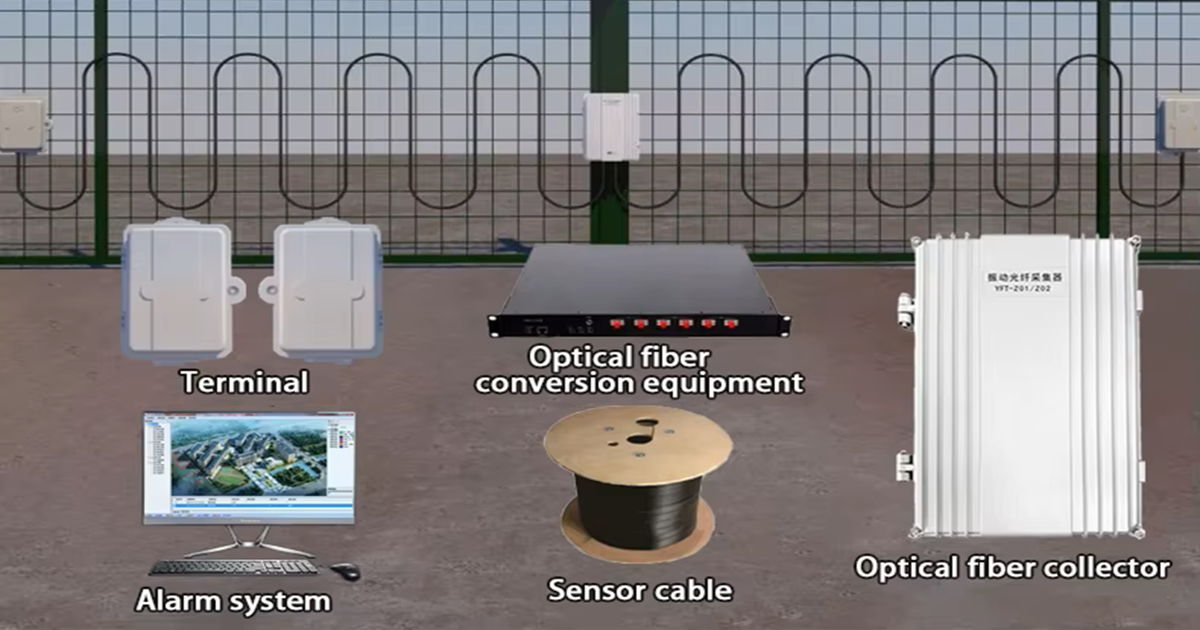

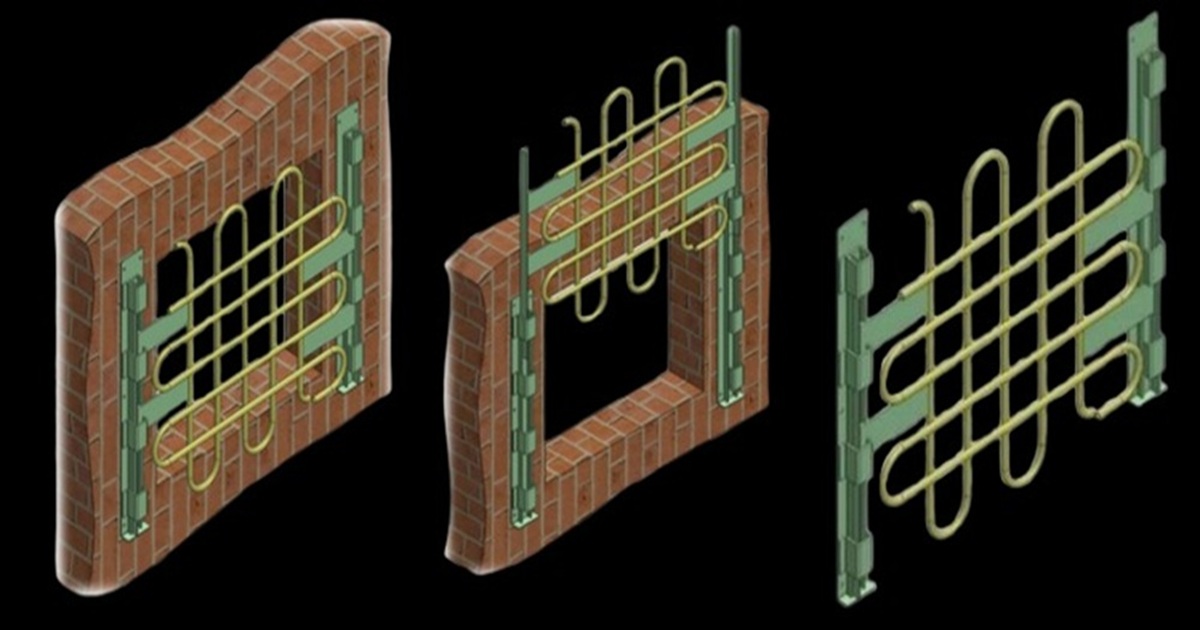

A UVIS station embeds rugged cameras and illumination in a shallow ramp or low-profile module. As a vehicle drives over at normal speed, the system stitches images into a continuous, high-definition view of the undercarriage. Software compares that view against a reference library for the same make/model or against the vehicle’s own prior scans. UVSS adds persistent observation panoramic cameras watch approach, stop, and exit lanes, while license plate recognition ties scans to identities and access logs for audit and investigation.

Where these systems are essential

Airports, seaports, refineries, chemical plants, data centers, embassies, correctional facilities, military bases, and event venues all face elevated risk. Anywhere perimeter penetration would be consequential, a UVIS/UVSS System Supplier brings consistency to inspections that human mirrors and quick glances cannot match. For border crossings and free-trade zones, high throughput and auditability are indispensable.

Spectron’s advantage

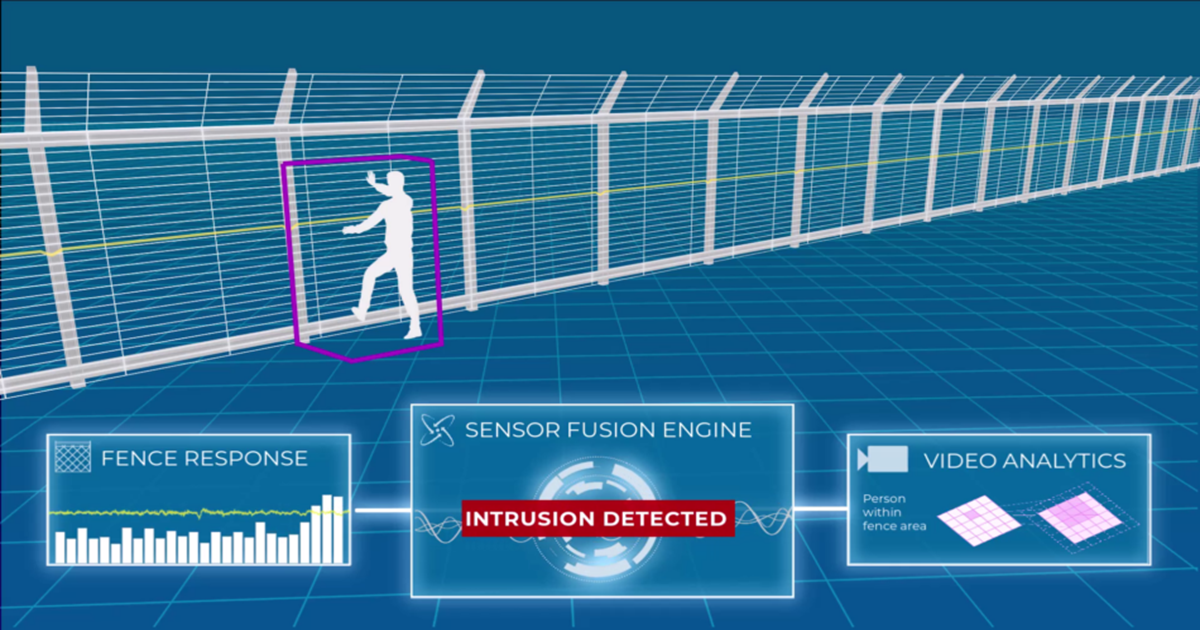

As an integrator and OEM partner, Spectron curates the right hardware for climate and traffic, then layers a mature software stack and workflow design. Systems are engineered for dust, heat, rain, and road salt, with IP-rated housings and shock-isolated optics. Illumination is designed to minimize glare on wet surfaces, preserving detail. On the software side, Spectron’s analytics highlight changes since last scan, detect missing bolts, fresh welds, and hidden cavities, and present operators with intuitive mark-ups, side-by-side comparisons, and a clear escalation path.

Features security teams rely on

- True color and monochrome imaging to balance detail across materials and lighting.

- Automatic vehicle detection, trigger control, and speed guidance for consistent captures.

- AI-assisted anomaly detection with confidence scoring and explainable highlights.

- Encrypted storage with tamper-evident logs for legal chain of custody.

- Integration with access control, bollards, boom barriers, and visitor management.

- Operator training modules and exam certifications to sustain proficiency.

Operational models

Some clients deploy UVIS on every gate; others use tiered screening, routing high-risk profiles to deeper inspection. Mobile UVIS units support temporary events or surge conditions. Spectron’s UVIS/UVSS System Supplier services include site surveys to place ramps where ground clearance, drainage, and turning radii support safe, smooth flow. Traffic studies inform lane counts and queue management to protect service levels.

Throughput without compromise

A common fear is that technology will slow operations. With proper lane design and pre-enrollment of frequent vehicles, scan times are seconds, and human review focuses on flagged anomalies. Dashboards show gate performance and SLA adherence. When anomalies are found, operators can mark and zoom regions, export case files, and trigger secondary search bays with minimal disruption to the main lane.

Resilience and lifecycle care

Outdoor electronics live hard lives. Spectron specifies heaters or blowers to prevent condensation, wipers or air-knives to clear lenses, and surge protection for unstable power. Routine calibration keeps geometric stitching accurate. Remote health monitoring alerts technicians before failures. Spare part kits and clear MTTR targets underpin maintenance SLAs so downtime stays low.

Safety and compliance

Drive-over modules are shallow, anti-skid, and load-rated for heavy trucks. Cable runs are protected from tire shear. Spectron aligns deployments with local road and electrical codes and with security frameworks used by airports, oil & gas, and defense sectors. Privacy controls manage data retention windows and access rights in accordance with policy.

Human-centered operations

Technology amplifies people. Spectron invests in operator ergonomics single-screen triage views, keyboard shortcuts for common actions, and color-blind-friendly overlays. Training emphasizes pattern recognition, escalation criteria, and interagency communication so the right teams see the right alerts at the right time.

Use cases and outcomes

- Airports: UVIS at airside gates catches tool drops, fluid leaks, and foreign objects before they reach the apron.

- Ports & free zones: Container truck scans deter smuggling compartments without slowing throughput.

- Refineries & chemical plants: Contractor vehicles are checked consistently shift after shift, reducing insider risk.

- Government compounds: Fleet vehicles build a clean history; deviations stand out immediately.

Clients report fewer manual undercarriage checks, better documentation, and faster investigations when incidents occur.

Future-ready capabilities

Computer vision continues to advance. Models trained on diverse fleets improve anomaly sensitivity while reducing false positives. Edge processing keeps analytics fast even when connectivity wavers. Multi-angle ramps capture deep suspensions and low-slung vehicles with equal clarity. Spectron’s roadmap as a UVIS/UVSS System Supplier includes integrations with explosive trace detection, driver ID, and under-bonnet thermal snapshots for a broader screening picture.

Costing and ROI

Budget holders evaluate total value: avoided incidents, reduced manual inspections, and improved compliance. Spectron offers purchase, lease, and managed-service options. For multi-site clients, standardized kits simplify spares and training, and analytics from all gates roll up to enterprise dashboards for risk and performance management.

How to implement with confidence

Start with a risk workshop: threat scenarios, gate volumes, peak curves, and response choreography. Spectron then proposes lane designs, ramp specs, camera counts, and integration points. A pilot lane proves image quality, AI hit rates, and operator workflow. After acceptance, rollout proceeds gate by gate with nightly cutovers to avoid daytime disruption.

FAQs

-

Can UVIS work in heavy rain or dust? Yes ingress-protected housings, sealed lighting, and adaptive exposure maintain usable images; routine lens clearing is automated.

-

What about low-clearance vehicles? Multi-angle camera arrays and ramp geometries maintain coverage without scraping vehicles.

-

Does AI replace human inspectors? No; AI prioritizes attention and explains anomalies, while trained operators make decisions within SOPs.

-

How long is data retained? Retention is configurable to your policy and regulations; case files can be archived for investigations.

Call to action

If your facility processes fleet traffic, contractors, or visitors at scale, upgrade undercarriage screening without slowing your gate. Engage Spectron as your UVIS/UVSS System Supplier to design a lane layout, analytics stack, and support model matched to your risk profile and throughput targets.